Lead with science, technology and human ingenuity to create transformative solutions in life sciences.

PI is the story of bold science, enduring partnerships, and a legacy over eight decades strong, built to reimagine a healthier planet. From deep roots in agri-sciences, we’ve expanded through PI Health Sciences into pharma and CRDMO, establishing PI as a life sciences powerhouse. From AI-discovered molecules to patented platforms in chemistry and biologicals, we connect the dots differently to deliver real-world breakthroughs. Driven by scientific depth and execution excellence, the PI way is to always think what’s next.

With science at its heart,

Pl has today evolved into

a powerhouse with a

purpose – to impact all

forms of life and transform

the future of planet health.

Mayank Singhal

Vice Chairperson & Managing Director

Our DNA

COURAGEOUS

CURIOUS

CREATIVE

CARING

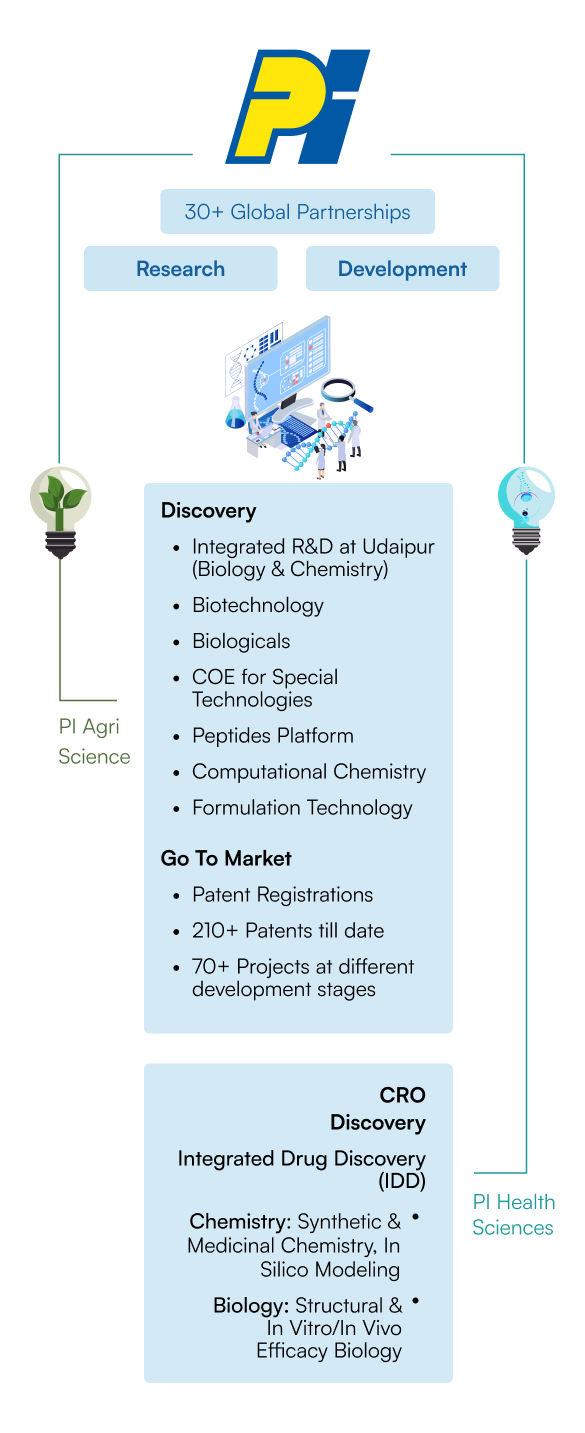

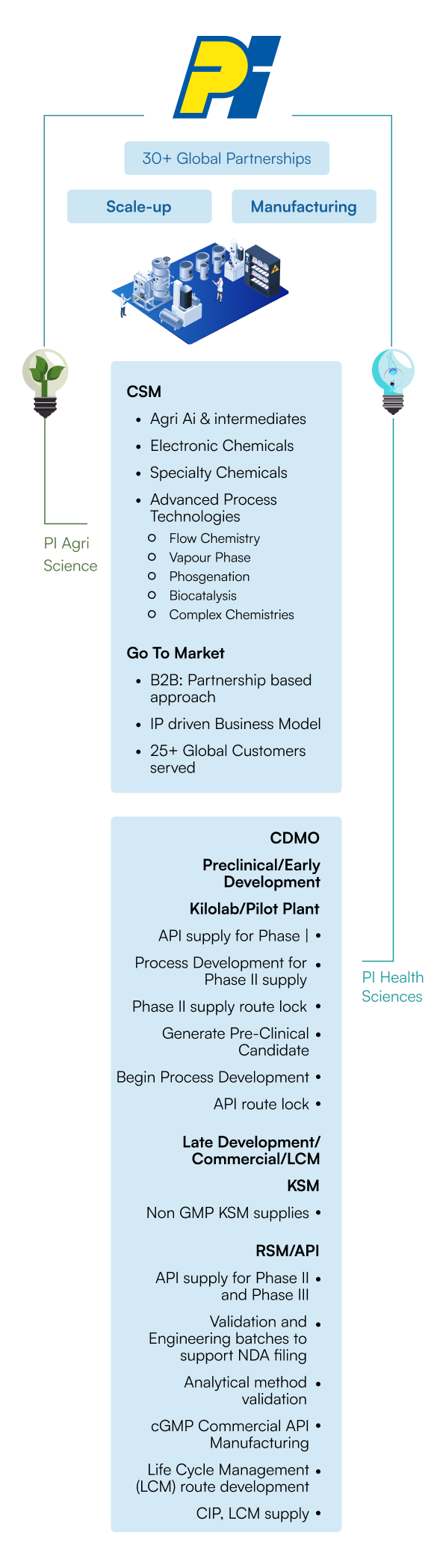

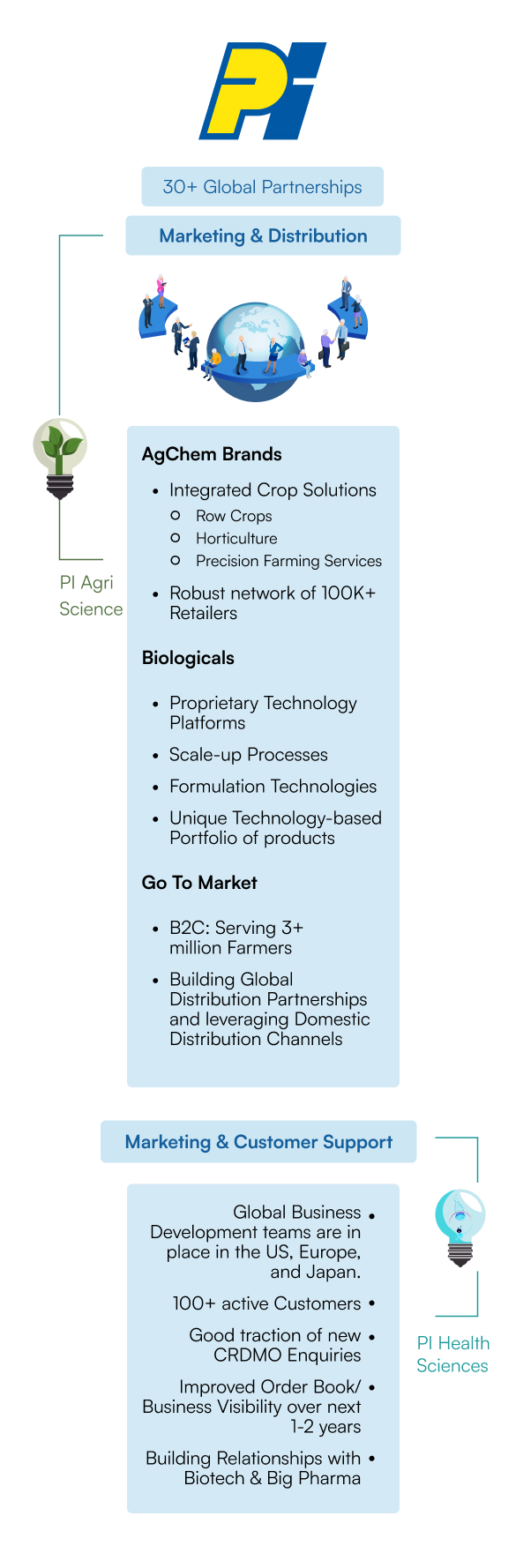

Our Business Model

Unique Global Business Model Founded on Trusted Partnership

PI Leadership

- Board of Directors

- Leadership Team

Mr. Narayan K. Seshadri

Non-Executive Chairperson

Mr. Narayan K Seshadri, with more than 42 years of distinguished corporate career, is a qualified Chartered Accountant who had started his business, consultancy career with Arthur Anderson. Joining KPMG afterwards, Mr. Seshadri rose to the position of Managing Partner of its business advisory practice in India. Mr. Seshadri had also worked with some large Fortune 500/ FTSE 100 companies to small start-ups in various international jurisdictions.

He is the founder and also serves as a board member of Tranzmute

Capital & Management Pvt. Ltd., which provides new ideas on

management and capital structuring to first generation entrepreneurs

and family businesses. Mr. Seshadri was among the earliest private

sector finance professionals to spot the opportunity in buying out

troubled companies and reviving them. He was the member of

Andersen’s Global CEO Advisory Council, the only Indian partner to

hold such a position.

Mr. Seshadri has been associated with the Company since 2006, he

took the reigns as Chairperson of the Company with effect from

October 5, 2016. During his tenure the Company has benefited

significantly from Mr. Seshadri’s expertise and experience across

multiple disciplines from financial, legal and regulatory, risk

management, corporate governance and human capital management.

Furthermore, he has played a pivotal role in setting the strategic

direction and growth plan while overseeing the Group’s businesses

policies and ensuring high governance standards.

His directorships and other full- time positions in bodies corporates are as follows:

- PI Industries Limited

- SBI Life Insurance Company Limited

- Max Healthcare Institute Limited

- TVS Supply Chain Solutions Limited

- Kalpataru Limited

- Re Sustainability Limited (Formerly known as Ramky Enviro Enginners Limited)

- India Debt Resolution Company Limited

- PI Health Sciences Limited

- CCIL IFSC Limited

- Kritdeep Properties Pvt Ltd

- Halcyon Resources & Management Pvt Ltd

- Halcyon Enterprises Private Limited

- A2O Software India Private Limited

- Tranzmute Capital & Management Private Limited

- Svasth - Heart India Foundation

- ERL Phase Power Technologies Limited, Canada

- Plant Health Care Inc, Nevada

- RICO Logistics Limited

- TVS Logistics Investment Ltd, UK

Mr. Mayank Singhal

Vice Chairperson & Managing Director

Having joined PI Industries in 1996, Mr. Mayank Singhal, an

Engineering and Management Graduate from UK, rose to become its

Joint Managing Director in 2004, its Managing Director and CEO in

2009 and subsequently PI’s Vice Chairperson and Managing Director

from 2019.

Leveraging his rich experience of over two decades in the fields of

chemicals, intermediate and agrochemical industries, he has played

an instrumental role in the rapid development of Company’s customer

base. He has also been responsible for bringing in superlative

changes in policies and transforming operations and systems, thus,

providing synergy to various business activities of the Company.

His directorships and other full- time positions in bodies

corporates are as follows:

- PI Industries Limited

- PI Health Sciences Ltd.

- TP Buildtech Pvt. Ltd

- Fratelli Wines Pvt Ltd

- Plant Health Care, Inc., Nevada

Mr. Rajnish Sarna

Joint Managing Director

Mr. Rajnish Sarna (DIN: 06429468) is a qualified Chartered

Accountant and has a diverse experience of over 3 decades in the

areas of Business Development & Strategy, Customer Relationship

Mgt., Operations, Finance, Risk Mgt, Legal Contracting &

Compliances, Investor relations, Information Technology and Process

Reengineering, etc.

He has been associated with PI for nearly 29 years and is

responsible for the overall transformation of the Company over the

last several years by managing numerous portfolios from Finance, IT,

Business Development, CSM operations, and Merger & Acquisition

related activities. His current role is focused on identifying new

business opportunities, Mergers & Acquisitions, evaluate and execute

such possibilities apart from various other strategic initiatives,

Investor relations, and handling joint-ventures and key customer

relationships on behalf of the Company and also Chief Investor

Relation Officer.

His directorships and other full- time positions in bodies

corporates are as follows:

- PI Industries Limited

- PI Life Science Research Ltd.,

- PILL Finance and Investment Ltd.,

- Solinnos Agro Sciences Pvt. Ltd.,

- PI Kumiai Pvt. Ltd,

- Jivagro Ltd,

- PI Fermachem Pvt. Ltd.,

- PI Bioferma Pvt. Ltd. (Formerly known as PI Enzachem Pvt. Ltd.)

- PI Health Sciences Ltd.

- Archimica S.p.A

- PI Flowtech B.V

- PI Health Sciences Netherlands B.V.

- Plant Health Care, Inc., Nevada

- Plant Health Care Plc, UK

Mr. Arvind Singhal

Non Independent - Non Executive Director

Mr. Arvind Singhal is a seasoned entrepreneur with over four decades

of diverse experience spanning industries such as mining and mineral

processing, agrochemicals and specialized chemicals, and electronic

metering systems.

He served as the Joint Managing Director of PI Industries for an

impressive 22 years before stepping down from the position in

December 2001. Subsequently, he continued to contribute to PI

Industries as an Independent Director until December 2006.

Currently, Mr. Singhal is the Managing Director of Wolkem India Ltd.

and also holds directorships on the boards of Secure Meters Ltd.,

Mynores India Pvt. Ltd., and the Federation of Indian Mineral

Industries (FIMI).

In addition to his corporate roles, Mr. Singhal is deeply involved

in various industry associations and chambers of commerce. He served

as the Patron of the Udaipur Chamber of Commerce & Industry (UCCI)

and is a Member of the Federation of Mining Associations of

Rajasthan (FOMAR). He is member of the Standing Committee for

Non-Metallic Minerals and Industries of FIMI and is an active member

of the National Committee on Mining of the Confederation of Indian

Industry (CII).

His leadership, vision, and vast expertise have made him a prominent

figure in the mining and mineral industries, as well as in the

broader business community.

His directorships and other full- time positions in bodies

corporates are as follows:

- PI Industries Limited

- Wolkem India Limited

- Secure Meters Limited

- Mynores India Private Limited

- Federation of India Mineral Industries

- Binarvi Reality LLP

Dr. T.S. Balganesh

Non Independent - Non Executive Director

Holding a PhD in Medical Microbiology from University of Calcutta,

Dr T.S. Balganesh completed his post-doctoral research at Brookhaven

National Lab, USA and Max Planck Institute, Germany. He has also

been awarded an honorary doctoral degree from the University of

Uppsala, Sweden. Possessing more than three decades of experience in

antibacterial drug discovery, Dr Balganesh served as Head of

Research at AstraZeneca’s antibacterial drug discovery unit in

Bangalore before rising to become the Managing Director and member

of the board of AstraZeneca India Pvt. Ltd. in the past.

His directorships and other full- time positions in bodies

corporates are as follows:

- PI Industries Limited

- PI Health Sciences Limited

- Plant Health Care, Inc., Nevada

- Ahammune Biosciences Private Limited

- GangaGen Biotechnologies Pvt. Ltd. Bangalore.

- Open Source Pharma India, Bangalore

- IKP, Hyderabad

Ms. Lisa Brown

Independent Director

Ms. Lisa J. Brown (DIN: 07053317), holds a Bachelor’s Degree in Law

from the University of Derby and is a registered Trade Mark

Attorney.

Ms. Brown has an extensive and rich experience of more than 2

decades in diverse sectors including, industrial, technology,

consumer etc. with an in-depth expertise on subjects like IP

management, compliance, risk assessment and corporate restructuring.

She has demonstrated value through an approach of risk based

analysis to deliver corporate growth, strategy execution and

governance through her various board and executive roles held in

reputed organisations like WABCO Holdings Inc., SSL International

Plc, London.

Mr. Shobinder Duggal

Independent Director

Mr. Shobinder Duggal holds a bachelor’s degree in economics (Hons.)

from St. Stephens College, Delhi University and is a member of

Institute of Chartered Accountants of India.

He has completed the International General Management program for

executive development from the International Institute for

Management Development, Lausanne, Switzerland. He has vast

experience in finance and accounts domain and in the past has held

positions at Nestle as well as Voltas India Limited. He is a

recipient of many prestigious awards, including the “Best CFO” of a

Large MNC by Business Today and Business World India, “Best CFO” of

an MNC by Dalal Street India, and the “Business World CFO” awards

acknowledged Nestle India for outstanding financial performance in a

Large MNC. He has also been recognized as one of India’s Best

Finance and Tech Leaders in the Yes Bank – Business World Best CFO

Awards in 2018.

During his association with Nestle, Mr. Duggal has handled various

responsibilities including Financial Planning; Direct Taxes;

Consolidation & Reporting to the Group and for the Indian entity;

Investor Relations; Insurance; Controlling; Costing; Treasury ;

Payroll; Fixed Assets Management; Operational & Financial audits;

Due diligence audit, etc. He led an international team for the due

diligence of a major acquisition in India. He has also handled

procurement and IS/IT for a period of time.

He has served as a member on the board of Nestle India Limited and

Nestle Lanka PLC.

He is a member of the advisory board of Haldiram Snacks and Ethnic

Foods.

His directorships and other full- time positions in bodies

corporates are as follows:

- SBI Life Insurance Company Limited

- Kirloskar Brothers Limited

- Sanofi Consumer Healthcare India Limited

- ABB India Limited.

Ms. Pia Singh

Independent Director

Ms. Pia Singh is a graduate from Wharton School of Business,

University of Pennsylvania, U.S.A., with a degree in Finance. She

has diverse business experience of over three decades. She is

currently a Director on the Board of DLF and the Chairperson of the

CSR Committee of DLF. Prior to that, she was the Chairperson of DLF

Retail Developers Limited and Director of DT Cinemas Limited.

She began her career in the risk-undertaking department of GE

Capital, an investment division of General Electric. Her area of

expertise includes business management, strategic planning, and

implementation.

She serves as a Trustee of Ananda Sangha Trust and Founder and

Trustee of Paramhansa Yogananda Public Charitable Trust. She is

Founder of Yogananda Films.

She serves on the Board of Advisors, College of Arts and Sciences,

University of Pennsylvania. She is also the President of the

University of Pennsylvania, Institute for Advanced Study of India,

and a member of the University of Pennsylvania Asia Campaign

Leadership Committee.

She serves on the Board of PI Industries Limited, Governing Board of

Indian Council for Research on International Economic Relations

(ICRIER) and Member of Advisory Council of Angel One Wealth.

Her directorships and other full time positions in Body Corporates

are as follows:

- PI Industries Limited

- DLF Limited

- Northern India Theatres Private Limited

- Sukh Sansar Housing Private Limited

- Solace Housing and Construction Private Limited

- Pushpak Builders and Developers Private Limited

- Arihant Housing Company

- Pure Home & Living Private Limited

- Madhukar Housing and Development Company

- Sambhav Housing and Development Company

- Udyan Housing and Development Company

- Anubhav Apartments Private Limited

- GHL Hospital Limited

Mr. Rafael Del Rio Donoso

Non-Executive Director

Mr. Rafael Del Rio Donoso is an Agricultural Engineer from

Pontificia Universidad Católica de Chile. He has other professional

qualifications as under:

- ALPs – Agribusiness Leadership Plus, Purdue University, West Lafayette, USA

- Marketing and Sales Excellence, Insead Singapore

- Advance Program in Strategy, San Paulo University

- Management & Strategy, Buenos Aires University

- Professional Development for communicators, Syngenta.

- Transition to General Manager, Columbia University

- Agribusiness/ Agriceutical seminar, Harvard Business School.

Mr. Rafael has an extensive and multicultural experience of more

than 20 years in agribusiness, strong leadership and strategic

vision. Mr. Rafael has been associated with the Syngenta Group

(1997-2023). He has served as Non-Executive Chairman on the board of

directors of Syngenta India till November, (2022-2023). Further, he

has also served as Leader of the territory for Syngenta India,

Pakistan, Bangladesh, Sri Lanka and Nepal, Member of the Board of

Directors of Syngenta Latin America based in Panama, President of

Syngenta Latin America North, President of ACC in Syngenta (Andean

Central America and Caribbean countries) Colombia.

His directorships and other full- time positions in bodies

corporates are as follows:

- PI Industries Limited

- Plant Health Care Plc

- Plant Health Care (UK) Limited

- Plant Health Care, Inc., Nevada

- Plant Health Care, Inc., Pennsylvania

- Campo Limpio, A Non-Profit Association

Mr. Vegulaparanan Kasi Viswanathan

Independent Director

Mr. Viswanathan joined the Bosch Group, Germany in August 1998 and

worked in its global headquarters at Stuttgart for about 2.5 years.

He took over as Joint Managing Director and CFO of Bosch Limited,

India in January 2001 responsible for all Commercial, Finance, IT,

HR matters besides Business Strategy. Under his leadership, Bosch

India witnessed a very strong and sustained growth through

continuous innovation, focused market-oriented approach and

excellence in execution thereby significantly enhancing value

creation for all stakeholders.

He was seconded to Robert Bosch, USA beginning 2006 as Senior Vice

President in the Automotive Electronics and Electrical Division,

North America and subsequently he became the Regional President of

the Automotive Electronics and Electricals division in Farmington

Hills, Michigan, USA. After successfully completing his assignment,

he returned to India as President and Country Head of Bosch Group in

India and Managing Director of Bosch Limited beginning 2008. During

his five years at the helm, the Bosch group recorded excellent

growth in sales turnover and profitability. After he superannuated

on December 31, 2012, he was appointed the Chairman of Bosch Limited

effective July 1, 2013, and stepped down after completing his tenure

in August 2019.

The Bosch Group in India boasts of six legal entities having a

combined turnover of more than Rs. 348 billion (~4.2 bin USD) in FY

2023-24 with a strong presence in Automotive Technology, Power

Tools, Security Technology, Packaging Technology, Hydraulics,

Embedded Software, Information Technology, Renewable Energy and

Consumer Durables. The group directly employs 39769 people in India

and is poised to scale even greater heights in the next decade

because of its strong foundation and market leadership. Prior to

joining Bosch, Mr. Viswanathan worked in Hindustan Unilever Ltd.

(HUL) in many senior positions both in India and abroad for 17

years. After working with Tata Consultancy Services for 5 years

(1977-1982), Mr. Viswanathan joined Lipton India Ltd, part of

Unilever Group as Management Accountant in 1982. He quickly rose to

the position of Commercial Manager (Beverages) in 1985. He played a

key role in transforming the loss-making Beverages business into a

strong and profitable division within a short period of 3 years.

He was later seconded to Unilever Head Quarters in London for a

3-year assignment as Audit Head with responsibility for all the

countries in Asia Pacific region.

He returned to Hindustan Unilever Limited in 1992 as Group

Treasurer. Later in 1993 he became Financial Controller and Head of

Mergers and Acquisitions and continued till 1998. During his stint

in Unilever India, many high profiles and big-ticket mergers and

acquisitions were successfully transacted, and a new group

architecture was designed and implemented by reorganizing and

restructuring the 7 Unilever companies into 1 consolidated entity

Hindustan Unilever Limited.

He was also on the board of several companies, including Bharti

Airtel Limited, ABB India Limited, HDFC Life Insurance Company

Limited, Magma HDI General Insurance Company Limited, TransUnion

CIBIL Limited, KSB Limited and is currently the Chairperson &

Independent Director of the Board at United Spirits Limited and a

Director of Royal Challengers Sports Private Limited.

He was also the President of Indo-German Chamber of Commerce in

2012-13.

Mr. Viswanathan is a Commerce Graduate from Madras University and a

Chartered Accountant from the Institute of Chartered Accountants of

India. He has attended advanced leadership training programs in many

prestigious institutions including Stanford University, USA. He has

a flair for teaching and has given many keynote speeches in many

national and international events.

His directorships and other full- time positions in bodies

corporates are as follows:

- Royal Challengers Sports Private Limited

- United Spirits Limited

Dr. Atul Kumar Gupta

CEO, CSM - AgChem

Mr. Prashant Hegde

CEO – AgChem Brands

Dr. Alexander Klausener

Chief Scientific Officer

Dr. Ramesh Subramanian

Global CEO - PI Health Sciences

Mr. Arunabha Raychaudhuri

Global Head - Supply Chain Management

Mr. Balasubramaniam Aiyaswamy

Chief People Officer

Mr. Sanjay Agarwal

Group Chief Financial Officer

Mr. Atanu Roy

Global Chief Information Officer

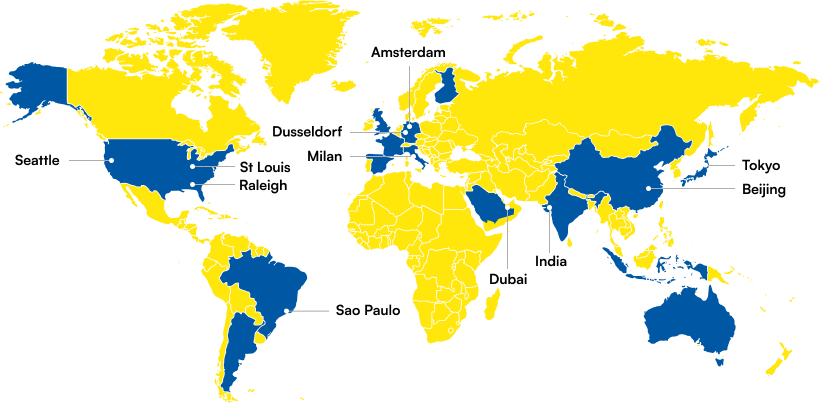

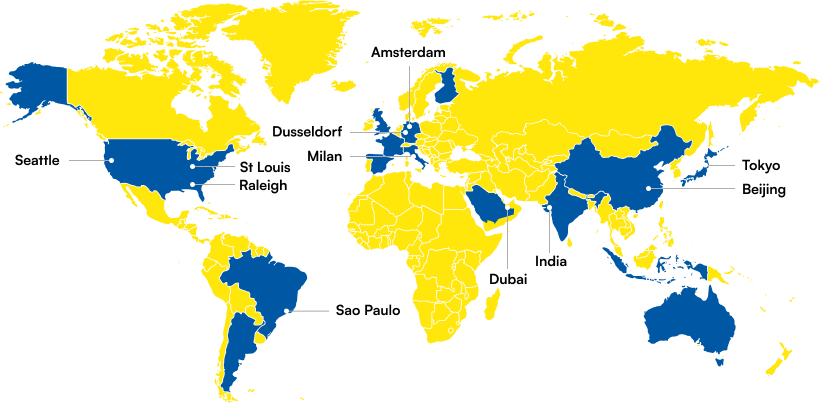

Global Footprint

Countries

Overseas Offices

Employees

Manufacturing Sites

Stock Points

Distributors

Retail Points

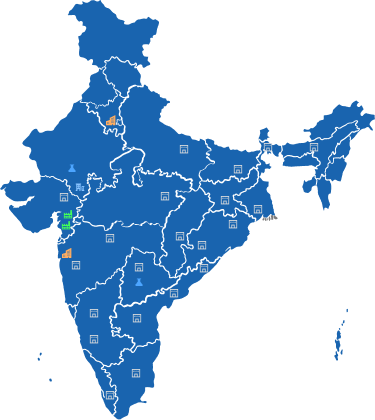

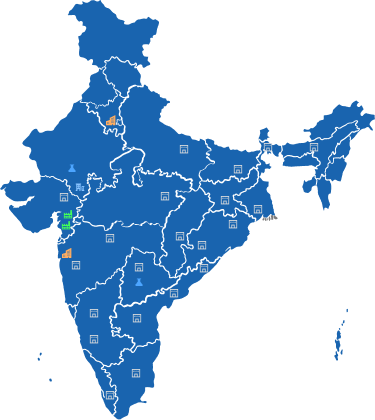

![]() Registered office

Registered office

![]() Corporate office

Corporate office

![]() R&D

R&D

![]() Manufacturing Unit

Manufacturing Unit

![]() Depots

Depots

Global Footprint

Countries

Overseas Offices

Employees

Manufacturing Sites

Stock Points

Retail Points

Distributors

![]() Registered office

Registered office

![]() Corporate office

Corporate office

![]() R&D

R&D

![]() Manufacturing Unit

Manufacturing Unit

![]() Depots

Depots

Capability Meets Capacity

PI Health Sciences - Hyderabad, India

PI Health Sciences - Hyderabad, India

PI Health Sciences - Hyderabad, India

PI Health Sciences - Hyderabad, India

Jambusar, India

Jambusar, India

Jambusar, India

Jambusar, India

Panoli, India

Panoli, India

Panoli, India

Udaipur, India

Udaipur, India

Udaipur, India

Udaipur, India